Thurston x WrxFlo: Driving Digital Transformation in Modular Manufacturing

Sourcing a Proven MRP System to Support Rapid Growth

Over the past seven years, Thurston Group has tripled in size - a trajectory powered by innovation, investment, and a clear ambition to lead the modular construction market. With plans to reach £104 million turnover by 2030, the business recognised that continued growth depended on one thing: smarter, standardised, data-driven operations.

To achieve this, Thurston set out to modernise its manufacturing backbone - integrating automation, eliminating paper-based processes, and creating full production visibility across all sites.

After evaluating multiple Material Requirements Planning (MRP) systems, the team selected WrxFlo, a cloud-based SaaS platform designed to identify inefficiencies, capture live production data, and drive continuous improvement.

Crucially, WrxFlo could integrate seamlessly with Thurston’s existing Enterprise Resource Planning (ERP) system - allowing the business to retain its valuable historic data while transforming how it was accessed and applied. The brief was ambitious but clear: give every manager the ability to drill into live project and customer data within three clicks.

The initiative was led by Production Director Dan Pollard and Production Manager Joe Hatfield, with strategic input from Managing Director Matt Goff and Finance Director Nick Petrovic. Collaboration across the business - from leadership to shopfloor - was key in ensuring the system worked in practice, not just on paper.

Overcoming Legacy Systems and Workforce Adoption Challenges

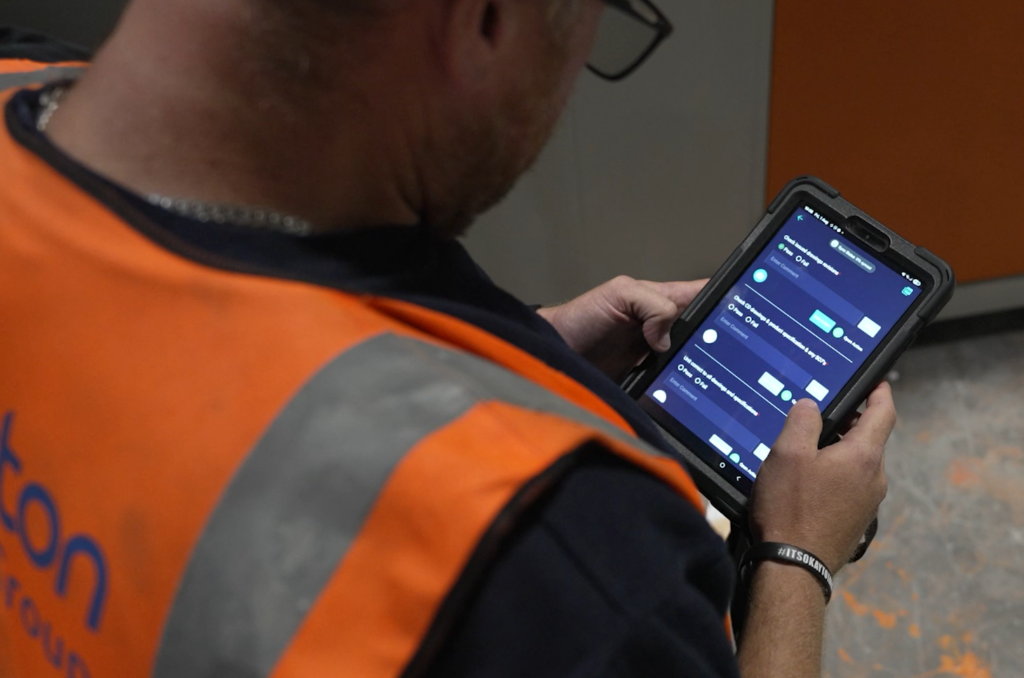

The greatest challenge wasn’t the technology - it was cultural. More than 350 operational staff would need to adapt to a new, digital-first way of working. Rather than imposing change, Thurston involved employees from the outset, giving them ownership of the process.

Teams participated in interface design, testing, and phased trials, helping to shape functionality and drive early buy-in. Initial pilots focused on digital job tracking, quality checks, and timesheet processes before rolling out across the wider operation.

To support this shift, Thurston also invested in upgrading its shopfloor infrastructure - establishing a solid foundation for data-led decision-making and future automation.

Embedding Digital Discipline Across Every Site

The WrxFlo implementation became a cornerstone of Phase 1 of Thurston’s Manufacturing Transformation Project (MTP) - a strategic programme to modernise operations and strengthen company culture.

Led by Dan Pollard, the project focused on four priorities:

Close collaboration between WrxFlo and Thurston’s internal teams ensured that the system reflected how people actually worked, not how software expected them to. Together, the teams defined success measures, refined interfaces, and built trust through co-creation.

The partnership also delivered a bespoke Customer Relationship Management (CRM) tool, giving the leadership team live visibility into performance data - from budgets and pipeline to project delivery metrics.

“This wasn’t about technology for technology’s sake,” says Dan Pollard, Production Director.

“We wanted a system that reflected how our people actually work - and gave them the information to do their jobs better.”

Building a Culture of Data-Led Decision-Making

Thurston invested £250,000 in the WrxFlo rollout, including a purpose-built sub-assembly area with digital displays and overhead signage aligned to machine operations. This investment also introduced 5S principles (Sort, Set in Order, Shine, Standardise, Sustain) - improving safety, flow, and organisation across the shopfloor.

The impact has been significant:

Thurston now operates with stronger data discipline, clearer accountability, and reduced waste and rework. More importantly, the business has established a scalable digital foundation for Phase 2 of its transformation - expanding automation, introducing AI-driven forecasting, and applying predictive maintenance powered by live equipment data.

Measured Results

| Outcome | Improvement |

| Production data captured digitally | 85%+ (up from almost zero) |

| Annual admin hours saved | 1,000+ |

| Reporting lag | Reduced from days to real-time |

| Material waste | –14% |

| Defect rates | –22% |

| Module cycle times | –18% |

| On-time delivery performance | +27% |

What the Team Says

Matt Goff, Managing Director, Thurston Group:

“The WrxFlo CRM has been a real step forward for our business. The visibility it gives me and my team across projects and processes is exceptional. We can drill into live customer and production data within seconds, helping us make faster, better-informed decisions and deliver more for our clients.”

Nick Petrovic, Finance Director, Thurston Group:

“WrxFlo is driving smarter buying decisions and stronger stock management. Before, it was a bit of a puzzle - now we’re planning proactively, improving communication, and aligning purchasing with production needs.”

Looking Ahead: Scaling the Digital Factory of the Future

With WrxFlo now embedded across operations, Thurston is already planning Phase 2 of its Manufacturing Transformation Project - scaling automation, linking performance data to predictive maintenance, and embedding AI-led forecasting to anticipate future demand.

The partnership with WrxFlo has proven that when technology and culture evolve together, transformation isn’t just achievable - it’s measurable.

Read our Other Recent News

FAQs – Cabins

Covering the most frequently asked questions about the cabins and relocatable building products offered at Thurston Group.

3 min read | Matt Goff

The key building and fire safety regulations we’re meeting and exceeding in 2025

To help you stay in the know of the current requirements for builders and offsite manufacturers, we’ve prepared a handy guide covering what the key UK building and fire safety regulations are heading into 2025.

3 min read | Marc Johnson